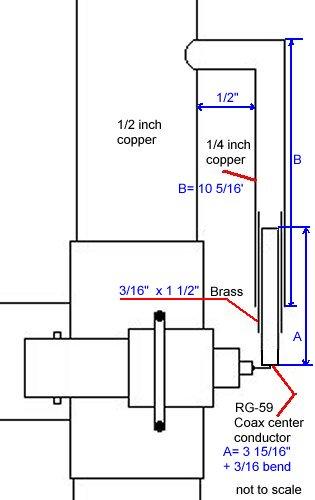

Copper Plumbing Pipe Dipole Antenna for 2 Meters by W4ZT |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

During the late 1980's I worked up the design for these dipoles during a vacation week at home. I was looking for an antenna design for a repeater antenna. The design I wanted was something that was grounded to help prevent static buildup problems, was easy to build and could be duplicated over and over without redesign. These dipoles are the result of that effort and do a good job. One of these dipoles works fine for a basic, slightly off center, omni-directional antenna. The angle of radiation is lower than that of a ground plane so it does tend to work better (by about 3db in the favored direction). You can use more than one by stacking them vertically and feeding them in phase. Each time you double the number of dipoles you increase the gain in the favored direction by about 3 db but the amount of work that goes into the phasing harness and the losses might make it undesirable to stack more than 2 or 4. Stacking distance is just under 39 inches tip to tip so a pair of dipoles will be about 12 feet long. I built 8 dipoles and did put all 8 up in phase. They worked great but were VERY long and the phasing harness was a bear to build and install. If you want to go that far I might be able to give you hints but you're on your own after that. ;-) If you build one of these antennas I'd love to hear from you and see pictures of your work. 73, Tony - W4ZT |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(Click on the small pictures to view a larger picture in a new browser window.) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Last update was on September 11, 2007 9:30